Product Center

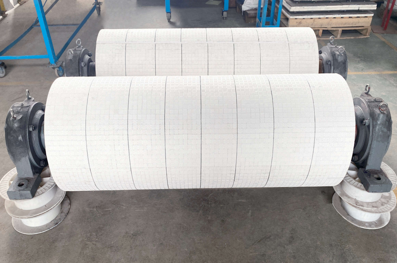

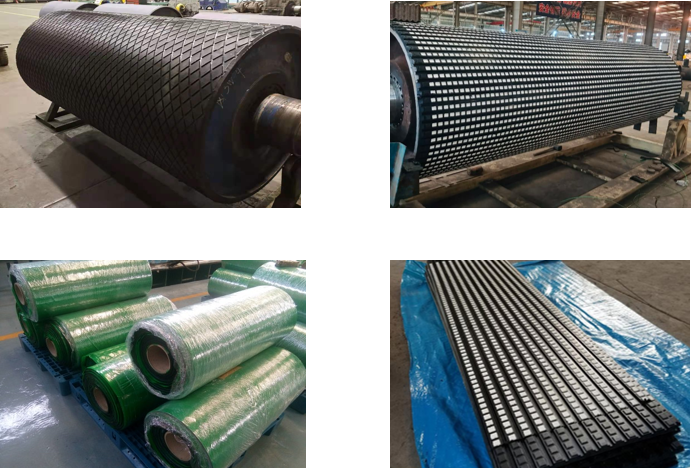

Pulley lagging is an important part and component of the conveyor belt system. The rubber coated roller can effectively improve the operation of the conveyor system and protect the metal roller from wear. Diamond or herringbone patterns, rubber coated surfaces of ceramic rubber plates can increase the friction on the surface of the rubber plate, effectively prevent the sliding friction between the roller and the belt, reduce the slippage of the belt, and reduce the adhesion of the material on the roller surface, thereby reducing the deviation and wear of the belt, improving the operating efficiency, and making the drum and the belt run synchronously to ensure the efficient and large-capacity operation of the belt. Widely used in: power plants, coal mines, cement plants, steel, metallurgy, coal, fertilizer, grain depots, ports and other industries.

Product Introduction:

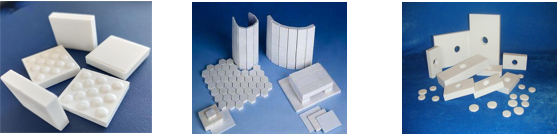

1. Unique Technology and Strong Bonding: The surface of the roller is made of highly wear-resistant alumina ceramics and is fixed to the conveyor belt roller by a special laying and bonding process.

2. High coefficient of friction, no slippage, no deviation: After long-term use, the surface of the traditional wear-resistant rubber layer becomes smooth due to wear, which can easily cause the belt to slip and deviate. The surface of the ceramic sheet is designed with unique bumps and high roughness. The coefficient of friction between the ceramic and the belt is large, so it is not easy to slip or run away during continuous operation.

3. Wear resistance and long service life: Alumina ceramics have high wear resistance. TINGSHENG produces various specifications of wear-resistant ceramics with Rockwell hardness (HRA) ≥ 85 or higher. The service life of the ceramic redirecting roller is the same as that of the traditional rubber lining. More than 8 times that of the roller.

4. Suitable for extreme working conditions: Ceramic rollers are suitable for extremely harsh conditions, such as high wear, easy sliding and moisture in the material or surrounding environment. It has been widely used in steel, metallurgy, coal, cement, power generation, ports and other industries.