Product Center

1:MODEL-FIBERGLASS COVER

Fiberglass protective covers have a variety of superior features that make them stand out among many decking materials.

Corrosion resistance: The main material of the fiberglass protective cover is an acid-alkali-resistant and corrosion-resistant resin. After an advanced curing process, the product has extremely strong corrosion resistance. Whether in a humid air environment or in acid-alkali corrosive liquids, the FRP decking can maintain its stable performance and is not easy to rust or corrode.

Wear resistance and anti-slip properties: During the production process of the FRP decking, the surface will be treated with wear resistance and anti-slip properties, so that the surface friction coefficient is moderate, which can not only effectively prevent the occurrence of slipping accidents, but also reduce the risk of slipping accidents.

High strength and light weight: The FRP deck plate uses high-strength resin and fiberglass composite materials, which makes the product high in strength and toughness. At the same time, due to the lightweight properties of the resin, the fiberglass deck is relatively light and easy to transport and install. Beautiful and aging-resistant: The appearance of the fiberglass deck has simple lines, and the silver appearance is modern and fashionable, in line with modern aesthetic needs. The surface is made of anti-aging, weather-resistant and anti-UV gel coat resin, which gives the product a long service life and maintains its beauty and stable performance even when used outdoors for a long time.

Fire retardant performance: The FRP deck has good flame retardancy, can effectively prevent the spread of fire, and reduce fire losses when a fire occurs. This feature makes FRP roofs have wide application value in situations requiring high fire protection requirements, such as power plants, gas stations, etc.

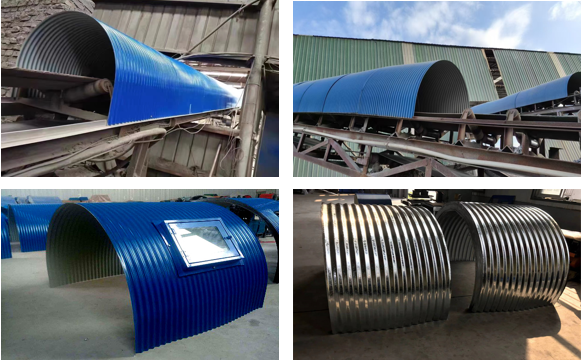

2:MODEL-METAL COVER

The protective covers and dust covers for belt conveyors produced and designed by our company are available in fixed, open and observation window types. You can see whether the material is being transported and whether the conveyor belt is running normally, and diversion switches.

The conveyor plays a role in preventing rain and dust. The rain cover of the conveyor belt adopts a unified installation and connection method, and various accessories are interchangeable. All protective covers of the conveyor belts are formed by flow machinery. The surface of the cover naturally forms dense arc-shaped reinforcing ribs, which are evenly distributed. The overall cover is shaped like a hyperbolic arc. The design has high mechanical strength, and the upper and lower parts of the cover are firmly interlocked. Excellent wind resistance.

Installation method: Our factory has carried out structural reforms and innovations on the basis of the installation and connection technology of the protective cover, making it convenient, practical, flexible to install and open, and beautiful in appearance. The corrugated fitting surfaces of the observation window, inspection door and shield are embedded with corrugated elastic rubber strips, which have good sealing performance.

The thickness of the shield material, the distance between the opening cover and the observation window and the size of the shield can be flexibly adopted. All accessories have been processed before leaving the factory, and our factory can also manufacture non-standard belts. Conveyor rain covers according to user needs and product bottom cover or baffle.